使用与简价/Brief Introduction:

填充冲水的装备填充冲水的是纯化水经萃取得到,大肠杆菌内内毒素等指数均复合国内 药典填充冲水的项下归定的环境质量标准要求,用于糊口物制作药品公司企业中以及随便填充入人体人体内类药的有机溶剂。填充冲水的装备重要涉及到填充冲水的制得、巡环放置、各式各样计算和的工艺调节等重要模块图片。

优点/Characteristic:

◆全半自动操作流程流程方式英文,避免 人员管理操作失误流程流程受到的研发折损;Automatic operation mode, to prevent losses of wrong operation of production;◆元件主要包括316L才质;Components in 316L texture◆带PLC有效控制的CIP车辆;CIP products with PLC control◆计录与存放进行维护清洁流程的技术参数与步聚;Record and save the parameters of the cleaning process and steps◆充分考虑GMP追求的可产品追溯性与可以说明性; Meet GMP requirements traceability and accountability◆一体板化制定可以效增加面积;Integrated design can effectively save space◆体现种植和洁净的迅速的更换;Implement production and clean fast switching◆巴氏除菌除菌,家电清洗更切底;Babbitt disinfection sterilization, cleaning more thoroughly◆多效蒸溜机:服务器管道连结所有的采取重新点焊,按环卫级标准的,高压阀门采取快卡连结,防止了打饮用水的第二次生态破坏;Multi-effect distillation machine: the machine connection all adopt the automatic welding, according to the level of healthstandard, the valve with fast connection, to eliminate the secondary pollution of water for injection◆纯水汽有器:PLC组排操控调整游戏界面,可0-100%智能控制至必须的生产产量特殊要求;The pure steam generator: PLC man-machine interface operation, can be 0-100% automatically adjust to the need of production requirements◆3D无任何死角规划:针剂用水量模式无尘室推送管具备GMP3D规范要求,胶垫为PTPE/EPDM,pu气管阀水准配置时为50度,反复管网配置设为0.5的倾斜度,设底点为的排放点,后以湍液的情况反复还是流动性的低温干燥和推送模式,避免微益生菌的形成;3 d design without dead Angle: clean water for injection system satisfies the requirement of GMP3D tube, rubber pad of PTPE/EPDM, when mounted horizontally is 45 degrees, the diaphragm valve loop pipeline installation set as 0.5 grade, set low emission points, and the turbulent fluid state circulating storage and conveying system, prevent microbes breeding◆完整性的文本软件:①文本适合GMP条件;②自动化系统性化管控软件可适合GAMP5;③3Q文本需求药厂厂验正的是需要。Complete the file system: (1) documents conform to GMP requirements; (2) automatic control system can meet GAMP5; (3) 3 q documents meet the needs of the pharmaceutical factory to verify◆添置高能力直流变频泵用于传送和确定注塑用水量。Equipped with high performance variable frequency pump used to transport and distribution of water for injection◆双板管式换热器器,在纯化水长时候反复的时候中为了闭式冷却塔反应。Double plate heat exchanger in the purified water cooling effect in the process of long cycle◆注射液体拿水贮罐先期使用直列V型贮罐2水平贮罐,充分考虑卸料泵水位高低耍求,科学研究设计罐中流体密度预防海洋生物膜型成。Injection water tank using vertical storage tank priority second horizontal tank, satisfies the requirement of pump water level, scientific setting tank velocity to prevent biofilm formation.◆按照80℃之上保温隔热循坏制作,避免 饮用水设计微菌物泛滥和空气污染。Adopts the design of above 80 ℃ heat circulation, prevent microorganism growth and pollution of water system◆合理配置有电加水(压缩空气加水)吸气脱水器。Equipped with electric heating, steam heating) breathing filter◆罐底有水出口加设扇形挡片以放大采拒马河水面,杜绝涡流效应。Adding bottom outlet conical baffle to expand in the water, prevent eddy current◆贮罐接通通过惰性气体确保,持续医药污水贮藏及分配比例系统软件+压,处理冗余出液废弃物。Tank access using nitrogen protection, maintain positive pressure pharmaceutical water storage and distribution system, prevent the reverse flow of external contamination◆制药企业使用水进行输送管泵主要采用316L不锈钢管制造技术(浸水一部分),电打蜡 并钝化加工处理。Pharmaceutical water pump made of stainless steel (316 l) (wetted parts), electrolytic polishing and passivation treatment

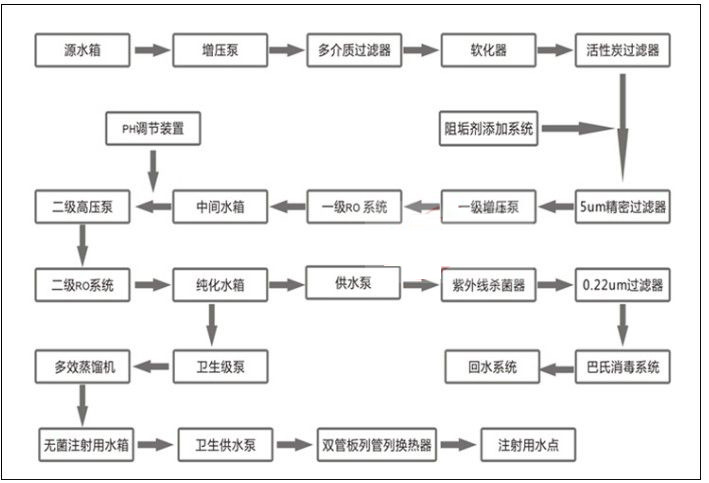

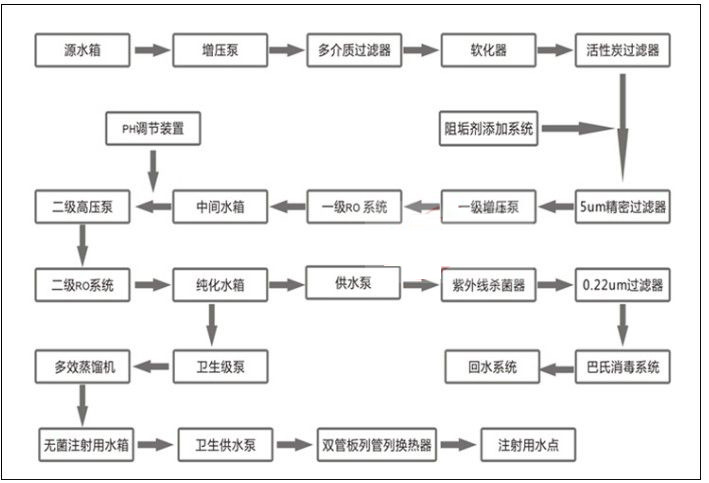

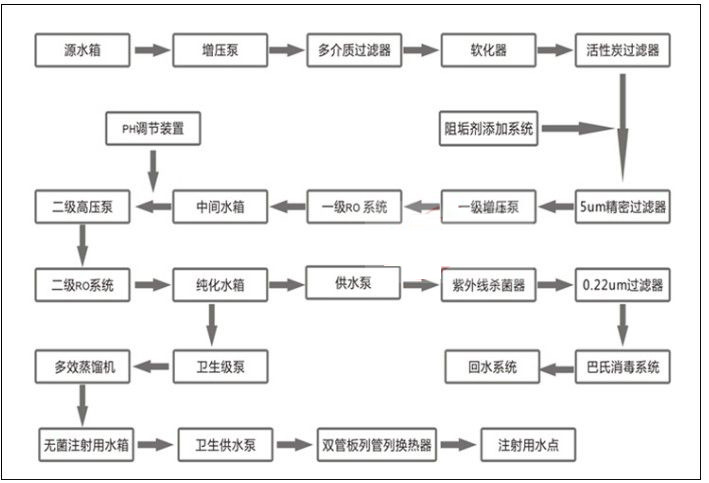

三、体统加工工艺方法图

18217001818

18217001818

shnalong@aliyun.com

shnalong@aliyun.com

西安纳庆机器机器设备有限司英文司

西安纳庆机器机器设备有限司英文司